Printing

Our device utilizes the Creality CR-30 3D printer as its base, which we selected for the “infinite z-axis” conveyor belt feature. This conveyor belt is capable of moving the substrate and print away from the nozzle, where a UV light will cure the deposited ink without risk of solidifying the ink reservoir. Once the conveyor belt returns to its original position, a new layer of different ink compound may be directly deposited on top and cured once more. This in-situ curing increases the working time of inks, while also reducing the need for a technician to manually relocate inks to a curing oven in traditional electrode manufacturing methods.

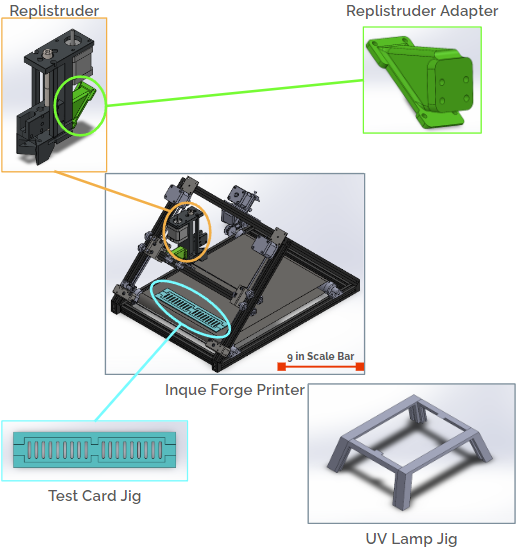

An open sourced CAD extrusion system, called the replistuder, is used to expel the conductive in lieu of a print head. The replistruder is then loaded with a needle and syringe. The syringe chosen for the replistruder is UV black opaque so the conductive inside the syringe barrel does not cure. The needles are flat tipped with UV bonded stainless steel. Because the CR-30 originally prints at a 45 degree angle, a mount was added to normalize the replistruder back into a vertical orientation.

Coding

Our developed code significantly simplifies the process of configuring print files for our printer. After users model and slice their designs using Creality Slicer, they can easily adapt the resulting files for our specific hardware. This streamlined workflow minimizes the technical barriers typically associated with conductive ink printing, making it more accessible to a broader audience. By reducing the complexity of the setup process, we enable users of varying skill levels to efficiently operate our device, thereby expanding the practical applications and adoption of conductive ink technology.

Curing

The conductive inks chosen used in printing electrodes require two methods of curing: ultraviolet and heat. The Creality CR-30 printer is equipped with an integrated heating component, a heatbed that can reach temperatures up to 100°C. For UV curing, a high power UV LED flood light is utilized. Our chosen UV lamp operates at a wavelength of 365 nm and an irradiance pattern of 650 uW/cm^3 at a distance of less than 12 inches. Using a UV lamp with LEDs can mitigate the risk of overheating, compared to mercury lamps.